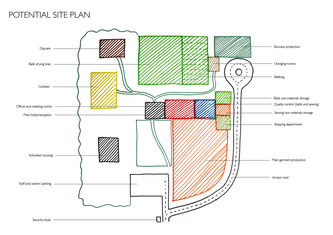

This was our last full week of work before presenting the project back to Global Mamas, and it was a busy one. With all the team back in Ghana, it was all hands on deck to produce attractive images of the design that would communicate the important features and show the design off to its best. We drew up the latest version of the site plan and developed the 3D model as far as we could in the time we had, concentrating especially on the sewing and batiking production spaces.

Last Saturday was the day of the presentation, and we held an event at the Global Mamas offices to mark the end of the summer architectural internship, and present all our work and the final conceptual design. There was a small but lively gathering of Global Mamas staff, volunteers and friends. We invited feedback and comments from the group and received some useful constructive criticism amid an overall positive response. We are very proud of the work we have done, and although there is a lot more still to be done to develop the design, I think we have produced a solid base from which the project can move to the next stage.

The next steps for ASF and Global Mamas will include drawing up a budget and detailed costing for the different elements of the design, starting to look around for suitable land for the site, and of course the all-important fundraising, without which the Fair Trade Zone will not be able to lift off the paper and into reality.

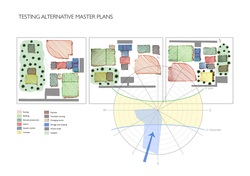

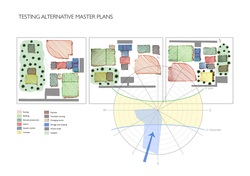

We had a challenging few weeks as a couple of members of the team had to temporarily depart to different continents. Interrupted Skype communications and expensive phone calls were the order of the day. Nevertheless we made headway with the design and spent a lot of time revising the master plan and testing different versions. We used local climate information, as well as narratives of the journeys that people and fabric will take through the site to inform the relationships

We started to build a 3D computer model of the site which we refined as the design became clearer. Glenn and Mae-Ling both architects working in Ghana came to the Global Mamas office to conduct design reviews with us, and these were very valuable in helping us to distill and focus the conceptual ideas behind the design.

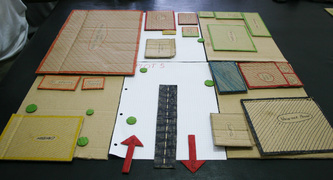

At the beginning of the week we made another participation model – this time of all the spaces needed for batiking. We went to Ashaiman (again!) to speak to the batikers and do a modelling exercise with them. It was very useful and some important criteria came out of it. For example, the batikers were very clear that they would like two different drying areas – one for after the fabric has been dyed, and a separate one for after the fabric has been dewaxed at the end, so that the finished fabric doesn’t get marked by flecks of old dye.

We then did the same exercise with the managers - Tasha, Amos and Dorcas. It’s always interesting to see how the responses differ, and one of the challenges of this project is to incorporate and reconcile the differing priorities of the management and the mamas.

We spent the rest of the week developing the master plan for the site which has been proving more difficult than we imagined! Especially as Global Mamas don’t yet have a physical site for the FTZ, so we are trying to develop a plan that can be adapted to the land they eventually acquire. I think there will be lots more sketching and experimenting before we come up with an optimal layout!

Emily

We’ve been up to a lot since we returned from Cape Coast. We spent the rest of last week recording graphically all the information we had collected during the trip. Have a look at the Gallery section to see some of our work, not just from the last week but from the project so far.

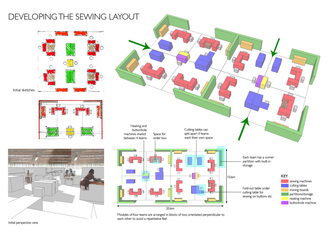

We also finally got down to some designing! We decided to start at the small scale with the layout for the sewing teams, and scale up from there. There was a fun afternoon spent sketching out different ideas and working out how much space will be needed for a team of three people working together to make the garments. Then we moved on to making some models that the Mamas could use to show us their ideas for the layouts. Using simple cardboard shapes, we modeled the components needed for the sewing workstations, and also all the spaces needed on the site as a whole.

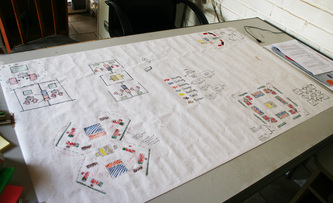

On Tuesday this week we took the models to Ashaiman, and continued our participatory design by asking focus groups of four women to arrange the components as they would like the real site laid out. We did the activity with four groups in total. The Mamas got really into it and were soon enthusiastically discussing different layouts. It was great to find out what they thought, and they came up with plenty of ideas we hadn’t considered!

The rest of this week has been spent analysing and testing the different layouts. I’ve been focusing on the sewing workspace and Kofi has been looking at the site plan. We’ve done some 3D modelling of different options, and now we can start designing the buildings in more detail.

Emily

Tuesday, the last day of our 4 day trip to Elmina was quite an experience, the best was definitely saved for last. We picked a fast car from cape coast to Saltpond where we were to meet Steve from Sustain Adinkra, who took us to visit a project he is working on at the moment. No one really knew what to expect from such a small town but our impressions on our arrival were pretty much the same and I’m sure everyone else was just as surprised as I was. The building though unfinished was AMAZING! Standing at two storeys high, the curved housing facility clad with raffia is definitely a sight to behold. The highlight of the trip was being a part of the building process, we all took parts in cutting and skinning the raffia members and hammering them in place to form a room partition. We also had the chance to build the walls for the outdoor rooms which were made of old car tyres. We cut, sewed together and filled the tyres with sand to form the walls. The walls of the bathrooms and toilets which were a few metres from the main building were made from concrete and glass bottles which reflected the light that shone on it, giving it a lovely effect. Steve then put us in groups and told us to create anything in forty minutes using the materials available. My team made up of Steinunn, Emily and myself tried to make a chair using raffia which didn’t exactly turn out the way we wanted it to! The other team made up of Andrews, Lisanne and Kofi made an unfinished room divider using a car tyre, raffia and empty bottles. The practical day gave us lots of ideas to incorporate into the FTZ proposal, the rest of the week we will be collating all the information we have collected on the trip to incorporate into our designs. Adjoa

Monday we started off doing a batiking workshop at the workplace of mama Martha. She talked us through the batiking process and helped us understand it more. We started off choosing the stamps we wanted to use for our patterns, while the wax was being heated. The mamas showed us how to dip the stamps in the wax and shake it off without getting the hot wax on yourself or somebody else. This was more difficult than it looks! When the patterns were finished it was time to choose a colour to dye the fabric with. After dyeing the fabric is hung outside to dry and we could see the colour changing from dark brown in the wet situation to orange in the dried situation. It looked amazing!

After the workshop Anna Rose and Patience, from Global Mamas, met us and took us to Cape Coast. Here we visited several other mamas at their businesses. In total we visited 3 seemstresses and 3 batiking workplaces. This gave us a good impression of how the mamas worked and what kind of space they need. We asked them questions on what they would like to change about their workplace, what they would like to improve or what could make their workplace a more comfortable place to work in. Most of the women had never really thought about it before. They are used to their place as it is and they like it.

After meeting the mamas we went to the Global Mamas office in Cape Coast. The office in Cape Coast is different from the one in Ashaiman. In Cape Coast the mamas have their own businesses and consider Global Mamas as one of their customers, whereas in Ashaiman there is one main building, which employs 24 people, where the whole process takes place under one roof. Patience showed us around at the office and walked us through the process. To make it more visual they picked a finished product from the shelf and moved it through the different stages of the quality control. This way it became clear how much is happening in such a small room.

Lisanne

Sunday saw us at the Oguaa Football for Hope Centre. The building, commissioned by FIFA and run by an NGO (Play Soccer Ghana) consists of a structure with facilities dedicated to education and public health as well as a small-size artificial turf football pitch. One of the staff members at hand, Gertrude, gave us a tour of the building and acquainted us with some of the challenges and successes of the programme. The centre runs on a 48-week curriculum and children aged 4-15 are invited to attend. The programme runs after school and every week a different skill is taught using football to engage, inspire and educate the children. Gertrude, our guide, was one of the first beneficiaries of the programme. To achieve its aim of public education, the building has facilities like classrooms, a library, internet cafe, laboratory, basic health care area and an office for staff members. The design uses sustainable construction techniques in innovative ways. The principal materials used in the design are bamboo and shipping containers. The containers serve as the main building envelope with the bamboo used as cladding. It has a roof of Perspex and aluminium sheets which allows light into the spaces below, the design also captures the breeze making the need for fans minimal. The team thought there were many ideas that we could use from this case study in the FTZ design. Kofi

Our second trip to Ashaiman was quite a fruitful endeavor. The first visit was to find out more about the batik making process so we could understand the process which would reflect in our design. This time, we had a chance to interact with some of the Mamas and ask them a few questions about what they would want to see in their new production facility.

Questions like “How can we make the space more comfortable?” “How can we make it more personal?” “What other spaces would you want to include in the new facility?”- were just a few of the questions we asked the Mamas. They were cooperative and gave us enough suggestions which we decided to include in our design. Some of the Mamas suggested separate rooms for storage, more natural lighting, better ventilation and an outdoor eating area.

With the batik makers their major concern was the size of their workspace, which was quite small and led to problems like the scent of the dye staying in the workspace and even going as far as disturbing the seamstresses due to poor ventilation. The seamstresses wanted more storage units for their items and different colours for their walls, some even suggested, LIME GREEN! In addition to this they asked for pictures and clothes on the wall as inspiration for them. We then came together as a team and translated these suggestions into sketches and process drawings.

Adjoa

Last weekend we took a four-day field trip to the Cape Coast area to continue our research into Global Mamas’ production processes, and start investigating local building materials. We had a busy itinerary, and after arriving at the beautiful Stumble Inn we got stuck straight in with a trip to a kindergarten school in Ayensu built by Arup Engineers as part of their international development programme, in partnership with the Sabre Trust. The school is made up of three separate classroom buildings, each housing a different year group, situated around a central open-air structure which is used as an outdoor teaching area. Bamboo, a locally available and sustainable material, is used as cladding, and for the structure and roof of the outdoor classroom. We also learnt about how the earth bricks were made, which are used to construct the walls. Paddy, one of the teachers even showed us inside and explained the educational programme that has been developed and implemented by Sabre to improve on the current standard of kindergarten education in Ghana. It was an inspiring project and useful for us to see how local building materials have been incorporated into the design. We continued on to a bamboo processing centre, where Sabre have been experimenting with ways to treat the bamboo so that it doesn’t get eaten by parasites. Here fresh bamboo is stripped to remove the outer layer, and then submerged in the treatment bath – a combination of borax and boric acid – and left for a few days, before being dried. The treated bamboo can then be used for building and is much longer lasting than untreated bamboo. Emily

We’ve had a great first week getting to grips with the brief, researching, and brainstorming ideas. We took a trip to Ashaiman, just outside Accra, where Global Mamas has a production facility that's in a converted house and not really fit for purpose. The aim of the visit was to meet some of the staff and find out more about their garment making process and the spaces they need. Amos, one of the managers, walked us through the process of batik making – where plain fabric is dyed, stamped with wax patterns, dyed again, and maybe stamped and dyed again, to produce beautiful coloured patterned fabric. The dyed fabric is hung out to dry under the sun and blows around in the wind.

Dorcas, the other manager, then showed us around the sewing areas, where batiked fabric is ironed, cut, and sewn into garments. Global Mamas has taken great care in the sewing room to arrange the machines so that none of the seamstresses have their backs to each other, and it is a cool, pleasant place to work. The women listen to music and chat while they work, and it is important that we maintain this friendly informal atmosphere in the new fair trade zone.

It was very exciting to see the fabric and clothes being made. However, it was also clear that Global Mamas could do with more space, and a building that is designed around their very specific needs, especially when it comes to batiking, which requires hot wax, lots of water, gas, and both semi-outdoor and outdoor spaces.

We spent the rest of the week sketching and mapping the production processes, as well as identifying challenges and opportunities for the new design. We researched the current worrying status quo of the garment industry around the world as a contrast to the new place of production we are going to create. We started collecting images of buildings and projects which have inspired us with their use of materials and/or technologies and have related these to our own design aims. It’s going to be a challenging, but very interesting project, and we’re excited to move to the next stage.

Emily

|